描述

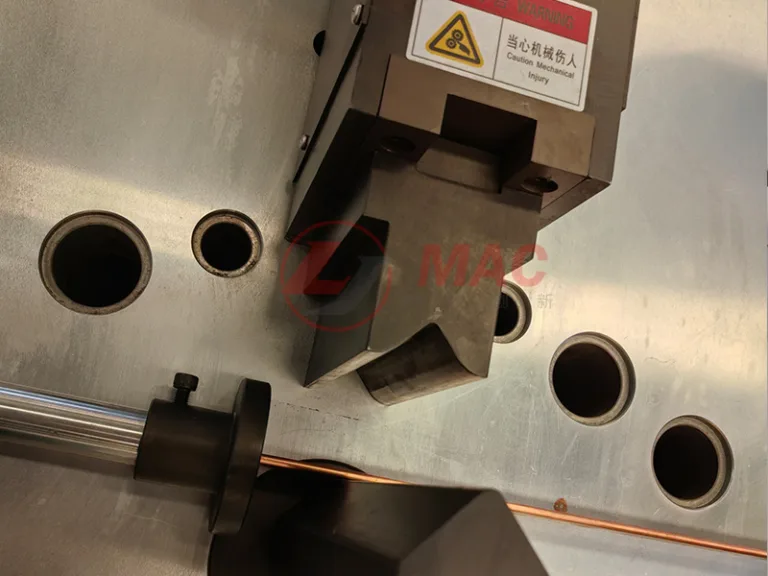

與此不同的是 NC.40ZB-1200NC.40ZB-2000型母線彎曲機是一款客製化機型,具有卓越的母線加工能力,能夠加工銅母線。 厚度最大可達 15 毫米,寬度最大可達 200 毫米,最大止動行程為 2000 毫米。.

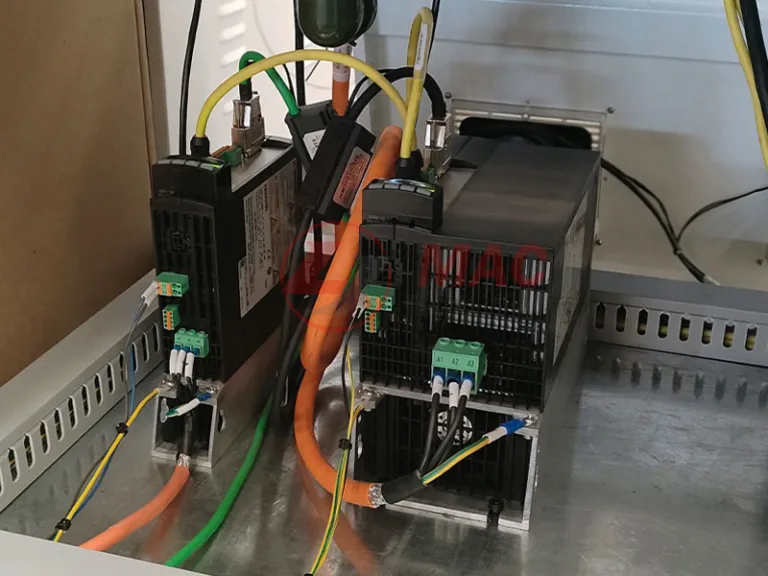

註:與液壓驅動的母線彎管機不同,我們的母線彎管機採用伺服馬達提供彎管力(最大400KN),比液壓系統更節能,精度更高。該系統專為高負載、高精度彎管而設計。

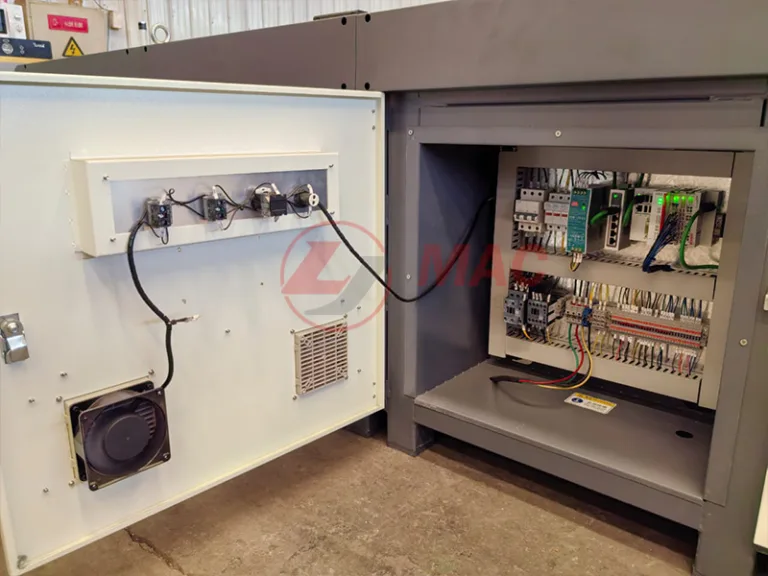

NC.40ZB-2000 採用現代化的易用型雙軸控制觸控螢幕進行程式設計和操作。彎曲角度可在初始彎曲後進行編程和調整。行程設定可在程式中隨時以 +/- 0.1° 的增量進行調整,以補償與材料相關的差異。該機器可以與…共享數據 CNC母線沖切機 透過 Wi-Fi,創建了一條自動化的母線沖孔、切割和彎曲生產線。

NC.40ZB-2000 母線彎曲機的慢速、自動和矯直模式均可透過腳踏開關或手動控制線進行操作。 可選的自動測量和重彎功能可確保無論材料特性如何,都能實現完美的彎曲效果。 對於每根母線,NC.40ZB-2000 銅母線彎管機都會先進行一次初始彎曲,測量後再進行二次彎曲,從而確保最高的製程可靠性和精度。控制系統會單獨計算所需的行程和回彈補償,以達到最佳精度。

產品影片

參數

| 模型 | NC.40ZB-2000 |

| 水平彎曲最大尺寸 垂直彎曲最大尺寸 | 15毫米 x 160毫米 |

| 垂直彎曲最大尺寸 | 12毫米 x 120毫米 |

| 壓力 | 400千牛 |

| 主軸行程 | 200毫米 |

| X軸伺服馬達功率 | 750瓦 |

| X軸行程速度 | 15米/分鐘 |

| Y軸伺服馬達功率 | 7.5千瓦 |

| Y軸行程速度 | 最快速度:5公尺/分鐘;最慢速度:1.25公尺/分鐘 |

| 彎曲誤差 | ±0.3° |

| 停止錯誤 | ±0.15毫米 |

| 塞子長度 | 2000毫米 |

| 電壓 | 380V 50HZ/60HZ(預設) |

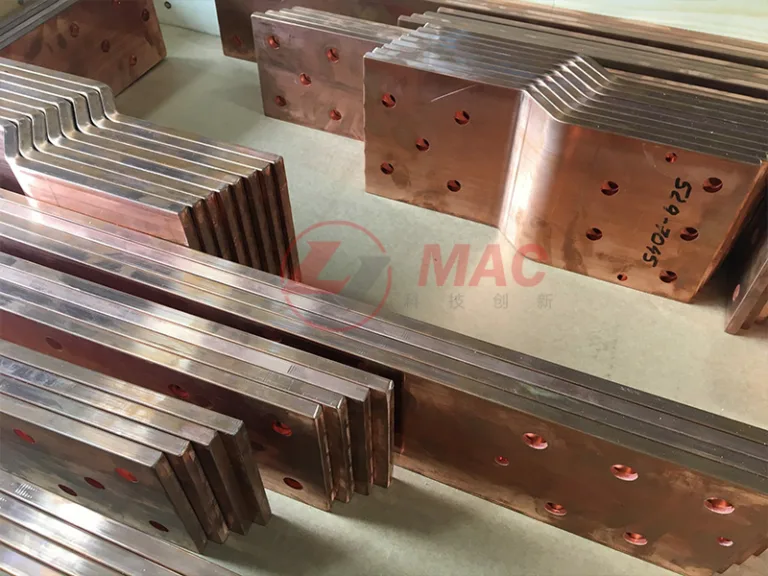

模具清單

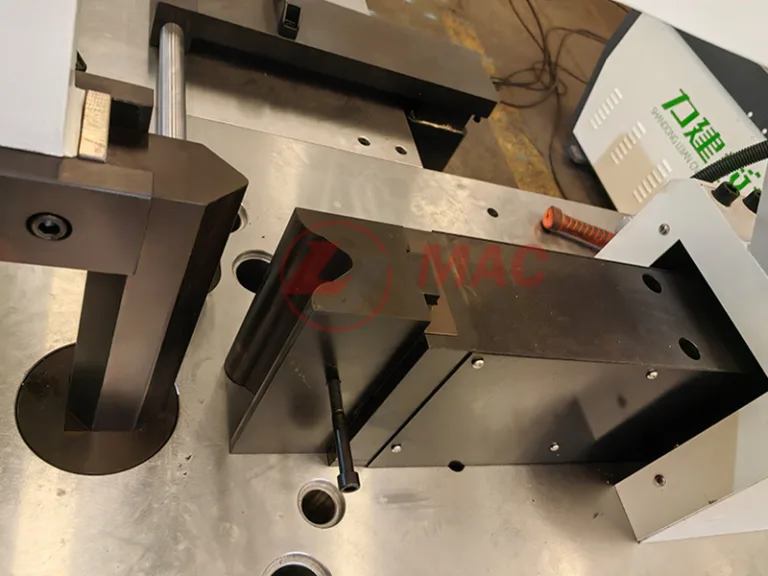

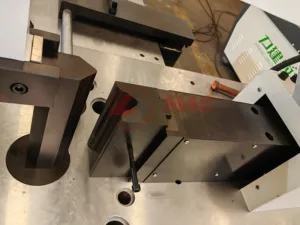

| 立式彎曲模具 | R5、R10 | 2套 |

| 水平折彎模具 | R30,R100 | 2套 |

筆記: 以上模具均為標準配置。如果您需要不同規格或特殊母線形狀的模具,我們的技術團隊可免費自訂。如需聯絡我們的技術工程師,請發送電子郵件至 lisa@busbarmac.com.

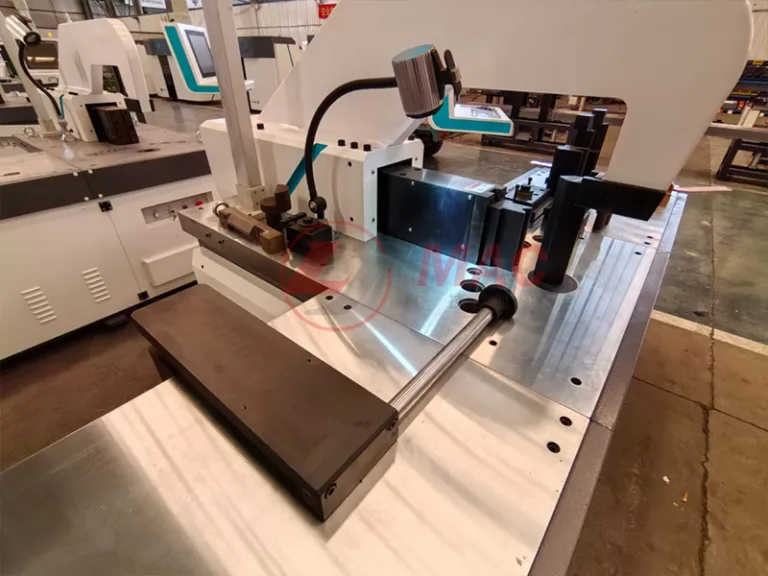

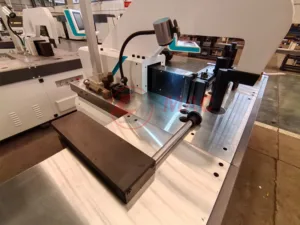

圖片庫

*此資訊不會與任何經銷商或個人分享。 我們對您的個人資訊的收集和使用。